Warfare in the past usually meant the clash of mass armies, with command and control during the chaos of battle exercised by flags, messengers, and portable radios. Generals even a few miles away struggled to interpret what they saw and heard amidst a flurry of reports. Now, military operations conduct asymmetrical warfare from thousands of miles away using a complex array of technology to monitor and attack small groups of enemies. Instead of massed artillery barrages or hordes of bombers, today’s military may operate a drone over hostile territory to support infantry to attack without infantry altogether. One company, in Fort Walton Beach, MAG Aerospace, manufactures technology that enables coordination, communication, and control in this new environment.

“What we do at MAG is everything it takes to ensure that a soldier comes home,” says Chad Vuyovich, MAG’s Director of Technology Insertion, Integration, and Interoperability Services. “We do this through the latest technology that supports the development and design of equipment and support for communication and weapons control systems integration.”

ISR stands for “Intelligence, Surveillance, and Reconnaissance.” MAG provides the design, construction and operational support of ISR command and control Operations Centers for ISR Unmanned Aerial Vehicles, and special mission aircraft (such as drones) data. MAG also provides 24/7 command and control, assured communications, ISR data processing, exploitation, dissemination and related IT services worldwide. This includes real-time dissemination of video, voice, intelligence, command and control, metadata and geospatial data for both government and commercial customers.

“ISR plays a role in the success or failure of every mission,” says Vuyovich. “MAG Aerospace facilitates the systems that coordinate ISR, and this landscape is always changing.”

MAG was founded in 2004 in Fairfax, Virginia, as the collaboration of four military servicemen. It has grown to more than 1,700 employees spanning six continents. MAG’s facility in Ft. Walton Beach employs approximately 100 people and primarily supports the U.S. Air Force Special Operations. MAG’s technologies are geared toward engineering ISR solutions, making them more efficient, so that ultimately the U.S. military personnel and assets are safer and more effective in their missions.

“Our technologies help personnel make better decisions and enable decision-makers to see what is happening at every moment,” says Vuyovich. “We do this with the creation of software and hardware that moves information faster. Many times, these are ‘one-off’ solutions that don’t apply across the board, but rather need bespoke technology for the problem presented. At its core, we specialize in integration and how we reach the optimum integration of systems is what sets MAG Aerospace apart.”

Best Practices

Overseeing a manufacturing company that specializes in the “unusual” requires a skilled team that is both adept with traditional and established communication and technological modalities, but also stays up-to-date on innovation and remains open to an environment grounded in constant adaptation. Those changing environments demand a skilled workforce and MAG is always seeking ways to engage talent.

“MAG Aerospace is not only a leader in the development of information systems, but their commitment to social responsibility is notable,” says Daniel Krug, a FloridaMakes Business Advisor who regularly consults with MAG Aerospace. “They are engaged with the experts in their industry, but they are also taking the lead in creating the educational pathways.”

MAG, one of the 10 finalists in the Florida Sterling Manufacturing Business Excellence Awards, was highlighted for outstanding social responsibility as a “best practice” amongst many other award criteria.

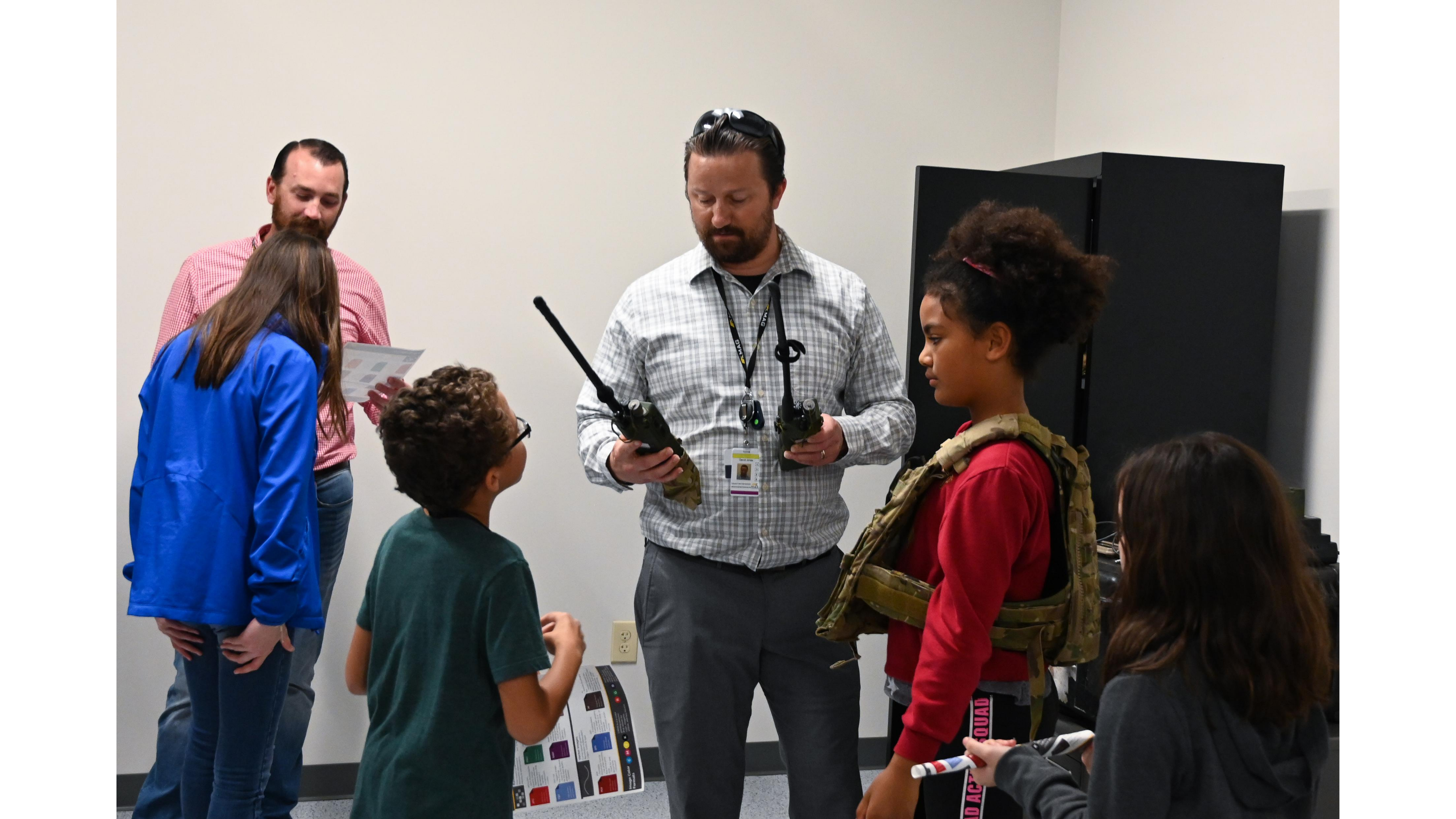

“Our industry, and those closely associated with what we do, face the same need from our workforce – an early exposure and education to STEM. We’re always looking for ways to inspire the next generation and bring them into the fold,” says Vuyovich.

Through partnerships with such organizations as the HSU Foundation, a coalition of educational organizations from eight coastal counties in Northwest Florida who share a common interest in transformational inspiration among STEM students, MAG Aerospace participates in a number of educational programs. Programs range from those that are centered around engaging students to full-day “boot camp” experiences that allow students to spend the day learning what it’s like to actually work at a company like MAG.

Through partnerships with such organizations as the HSU Foundation, a coalition of educational organizations from eight coastal counties in Northwest Florida who share a common interest in transformational inspiration among STEM students, MAG Aerospace participates in a number of educational programs. Programs range from those that are centered around engaging students to full-day “boot camp” experiences that allow students to spend the day learning what it’s like to actually work at a company like MAG.

MAG also has worked with local community colleges to create a “skill bridge” that helps open the pathway to STEM-related jobs by way of courses, internships and employment.

“Many times, the skillset we need is really hard to find, so instead of always having to recruit from around the world, we wanted to take the lead and make the investment and commitment locally to create those classes or programs that grow the talent for the jobs in our industry,” says Vuyovich.

The SMBE Awards Process

MAG Aerospace represents a new and innovative way of looking at manufacturing. Because MAG’s products combine information and technology, the end product isn’t what most people consider when they think of a manufacturing plant with an assembly line.

“When you are making systems that are about integration, this often results in the unification of multiple systems and sometimes the invention of a system,” says Vuyovich. “We have been active in the manufacturing community for many years and were thrilled to be nominated as a finalist.”

MAG Aerospace cites their participation with Florida’s Great Northwest (a regional economic development council) and the Northwest Florida Regional Manufacturers Council as integral not only to the SMBE nomination but to their success in their sector.

“Our local partnerships have fostered an exchange of ideas and a network of contacts that has strengthened our presence in the community and contributed to our work,” Vuyovich says. “Many people might not realize how the work of manufacturers in Northwest Florida has an impact on the rest of the world, but because of our work and the work of our partners here, we’re all working to help keep people safe.”

#ManufacturersBestPractices